General Testing

Key competencies

- Measure, quantify, qualify, monitor, ensure quality, performance and shelf life.

- Ability to create tailor-made protocols adapted to the desired approach, integrating the measurement and evaluation of all types of parameters and adapted to all budgets.

- Ability to transform assessments into recommendations for improvement.

- Our quality system follows the rules of ISO17025 guaranteeing the accuracy of our measurements.

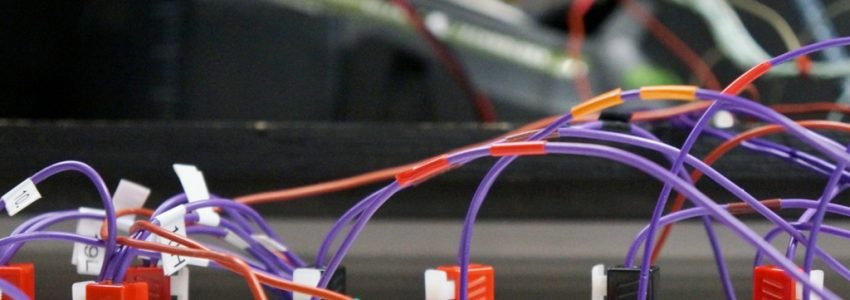

- All Electrical and EMC safety tests on all types of consumer and professional electrical products.

- Electronic and electrical measurement: voltage, frequency, capacitances, resistances, power and energy consumption.

- Measurement of electrical cable diameter.

- Testing all voltages, all frequencies (Japan, United States, Brazil, etc.)

- Dielectric strength, earth continuity, insulation resistance, leakage current.

- Tests in climatic chambers programmable in temperature and humidity from -50 ° C to 1000 ° C and humidity.

- Thermal Shock.

- Moisture Resistance Tests.

- Salt spray tests to assess the corrosion resistance of materials.

- Measurement and temperature analysis at the infrared camera.

- Testing of flammability and resistance to plastic fires (glow wire, needle flame ...)

- Measurement of brightness, noise.

- Temperature measurements, heating, black corner tests.

- UV resistance.

- X-ray for non-destructive fault analysis of products.

- Resistances and holding of markings.

- Realization of sampling and control of chemical, bacteriological and biological analysis with our neighboring COFRAC partner laboratory.

- Measurement of forces, torque, speed, breaking strength

- Testing of torsional strength of cables

- Engine test bench (MAGTROL bench) electric and thermal

- Impact Testing

- Pressure Measurement and Pressure Testing

- Leakage test.

- Multiple benches and automated endurance robots to simulate the life of components, subassembly, or finished products or applications, fault analysis, root cause search and action plan development.

- Consumer endurance semi-automated or manual.

- Dimensional measurement and capability.

- Functional verification software embedded product or application.

- Analysis of defects on products from returned markets for implementation of quality improvement plan.

- Analysis of products from claims or customer disputes.

- Risk analysis according to the identified defects and determination of the market occurrence.

- Creation of a performance evaluation protocol for any type of product in benchmark or absolute.

- Development of customer or normative test devices.

- Support for the creation of test laboratories, identification of needs, research of appropriate measurement and testing facilities, negotiation, implementation and teams training of team

- Development of instrument and test procedures

- Quality inspection: Intervention on customer site, on stock, at port, at suppliers and factories.

- Accompanying the laboratories involved in the quality process.

- Consulting in metrology.

- Trials with legal caliber for expertise justice and/or marketing claim.